| LAGereInheicht Nr. | Bohrungsdurchmesser | Abmessungen (mm) | Lagernr. | Wohnnr. | Gewicht | ||||||||

| in | mm | a | e | i | g | L | N | E | S | (kg) | |||

| SUCF201 | 12 | 86 | 64 | 15 | 11 | 25.5 | 12 | 33.3 | 12.7 | SUC201 | SF203 | 1 | |

| SUCF201-8 | 1/2 | SUC201-8 | SF203 | 1 | |||||||||

| SUCF202 | 15 | SUC202 | SF203 | 1 | |||||||||

| SUCF202-10 | 5/8 | SUC202-10 | SF203 | 1 | |||||||||

| SUCF203 | 17 | SUC203 | SF203 | 1 | |||||||||

| SUCF203-11 | 28.11 | SUC203-11 | SF203 | 1 | |||||||||

| SUCF204 | 20 | 86 | 64 | 15 | 12 | 25.5 | 12 | 33.3 | 12.7 | SUC204 | SF204 | 0.95 | |

| SUCF204-12 | 3/4 | SUC204-12 | SF204 | 0.95 | |||||||||

| SUCF205 | 25 | 95 | 70 | 16 | 14 | 27 | 12 | 35.8 | 14.3 | SUC205 | SF205 | 1.2 | |

| SUCF205-14 | 7/8 | SUC205-14 | SF205 | 1.2 | |||||||||

| SUCF205-15 | 15/16 | SUC205-15 | SF205 | 1.2 | |||||||||

| SUCF205-16 | 1 | SUC205-16 | SF205 | 1.2 | |||||||||

| SUCF206 | 30 | 108 | 83 | 18 | 14.3 | 31 | 12 | 40.2 | 15.9 | SUC206 | SF206 | 1.89 | |

| SUCF206-17 | 1.-11.16 | SUC206-17 | SF206 | 1.89 | |||||||||

| SUCF206-18 | 1-1/8 | SUC206-18 | SF206 | 1.89 | |||||||||

| SUCF206-19 | 1-3/16 | SUC206-19 | SF206 | 1.89 | |||||||||

| SUCF206-20 | 1-1/4 | SUC206-20 | SF206 | 1.89 | |||||||||

| SUCF207 | 35 | 117 | 92 | 19 | 15.5 | 34 | 14 | 44.4 | 17.5 | SUC207 | SF207 | 2.39 | |

| SUCF207-20 | 1-1/4 | SUC207-20 | SF207 | 2.39 | |||||||||

| SUCF207-21 | 15/16 | SUC207-21 | SF207 | 2.39 | |||||||||

| SUCF207-22 | 1-3/8 | SUC207-22 | SF207 | 2.39 | |||||||||

| SUCF207-23 | 1-7/16 | SUC207-23 | SF207 | 2.39 | |||||||||

| SUCF208 | 40 | 130 | 102 | 21 | 15.5 | 36 | 16 | 51.2 | 19 | SUC208 | SF208 | 2.79 | |

| SUCF208-24 | 1-1/2 | SUC208-24 | SF208 | 2.79 | |||||||||

| SUCF208-25 | 1-9/16 | SUC208-25 | SF208 | 2.79 | |||||||||

| SUCF209 | 45 | 137 | 105 | 22 | 17.5 | 38 | 16 | 52.2 | 19 | SUC209 | SF209 | 3.18 | |

| SUCF209-26 | 1-5/8 | SUC209-26 | SF209 | 3.18 | |||||||||

| SUCF209-27 | 1.-11.16 | SUC209-27 | SF209 | 3.18 | |||||||||

| SUCF209-28 | 1-3/4 | SUC209-28 | SF209 | 3.18 | |||||||||

| SUCF210 | 50 | 143 | 111 | 22 | 17.5 | 40 | 16 | 54.6 | 19 | SUC210 | SF210 | 3.68 | |

| SUCF210-30 | 1-7/8 | SUC210-30 | SF210 | 3.68 | |||||||||

| SUCF210-31 | 1-15/16 | SUC210-31 | SF210 | 3.68 | |||||||||

| SUCF211 | 55 | 162 | 130 | 25 | 19.5 | 43 | 19 | 58.4 | 22.2 | SUC211 | SF211 | 3.4 | |

| SUCF211-32 | 2 | SUC211-32 | SF211 | 3.4 | |||||||||

| SUCF211-34 | 2-1/8 | SUC211-34 | SF211 | 3.4 | |||||||||

| SUCF211-35 | 2-3/16 | SUC211-35 | SF211 | 3.4 | |||||||||

| SUCF212 | 60 | 175 | 143 | 29 | 19.5 | 48 | 19 | 68.7 | 25.4 | SUC212 | SF212 | 4.17 | |

| SUCF212-36 | 2-1/4 | SUC212-36 | SF212 | 4.17 | |||||||||

| SUCF212-38 | 2-3/8 | SUC212-38 | SF212 | 4.17 | |||||||||

| SUCF212-39 | 2-7/16 | SUC212-39 | SF212 | 4.17 | |||||||||

| SUCF213 | 65 | 187 | 149 | 30 | 23 | 50 | 19 | 69.7 | 25.4 | SUC213 | SF213 | 5.32 | |

| SUCF213-40 | 2-1/2 | SUC213-40 | SF213 | 5.32 | |||||||||

| SUCF213-41 | 2-9/16 | SUC213-41 | SF213 | 5.32 | |||||||||

| SUCF214 | 70 | 193 | 152 | 31 | 23 | 54 | 19 | 75.4 | 30.2 | SUC214 | SF214 | 5.92 | |

| SUCF214-42 | 2-5/8 | SUC214-42 | SF214 | 5.92 | |||||||||

| SUCF214-43 | 2-11/16 | SUC214-43 | SF214 | 5.92 | |||||||||

| SUCF214-44 | 2-3/4 | SUC214-44 | SF214 | 5.92 | |||||||||

| SUCF215 | 75 | 200 | 159 | 34 | 23 | 56 | 19 | 78.5 | 33.3 | SUC215 | SF215 | 6.65 | |

| SUCF215-45 | 2-13/16 | SUC215-45 | SF215 | 6.65 | |||||||||

| SUCF215-46 | 2-7/8 | SUC215-46 | SF215 | 6.65 | |||||||||

| SUCF215-47 | 2-15/16 | SUC215-47 | SF215 | 6.65 | |||||||||

| SUCF215-48 | 3 | SUC215-48 | SF215 | 6.65 | |||||||||

| SUCF216 | 80 | 208 | 165 | 34 | 24 | 58 | 23 | 83.3 | 33.3 | SUC216 | SF216 | 7.89 | |

| SUCF216-50 | 3-1/8 | SUC216-50 | SF216 | 7.89 | |||||||||

| SUCF217 | 85 | 220 | 175 | 36 | 25 | 63 | 23 | 87.6 | 34.1 | SUC217 | SF217 | 9.18 | |

| SUCF217-52 | 3-1/4 | SUC217-52 | SF217 | 9.18 | |||||||||

| SUCF218 | 90 | 235 | 187 | 40 | 26 | 68 | 23 | 96.3 | 39.7 | SUC218 | SF218 | 11.2 | |

| SUCF218-56 | 3-1/2 | SUC218-56 | SF218 | 11.2 | |||||||||

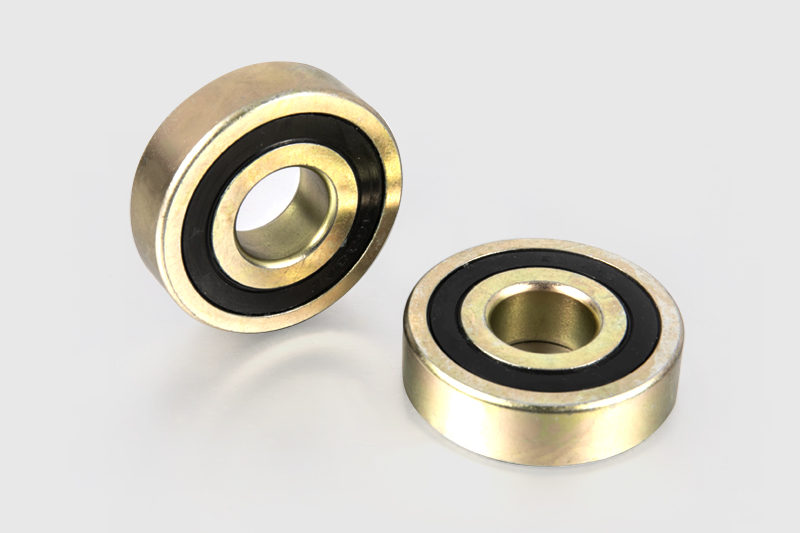

AISI 440C-Material:

Höhere Rost- und Korrosionsbeständigkeit als 52100 Chromlagerstahl. Bitte beachten Sie, dass AISI 440C magnetische Eigenschaften hat.

Chemische Zusammensetzung: C: 0,95–1,20, Si ≤ 1,00, Mn ≤ 1,00, P ≤ 0,04, S ≤ 0,03, Cr: 16,0–18,0, Mo: ≤ 0,75

AISI 304-Material:

Edelstahl AISI 304, der häufig als korrosions- und hitzebeständiger Stahl sowie als nichtmagnetischer Stahl verwendet wird, eignet sich für korrosive Umgebungen, in denen

Edelstahl AISI 440C kann nicht verwendet werden.

Chemische Zusammensetzung: C≤0,08, Si≤0,75, Mn≤2,00, P:0,045, S:0,03, Cr:18,0-20,0, Mo:8,0-10,5, Ni≤0,10

AISI 316L-Material:

316L-Edelstahl, der im Vergleich zu herkömmlichen Stahl- und 440-Edelstahllagern Korrosionsbeständigkeit bietet.

316L Stainless ist der standardmäßige molybdänhaltige Edelstahl. Das Molybdän verleiht 316 insgesamt bessere Korrosionsbeständigkeitseigenschaften als Grad 304.

besonders höhere Beständigkeit gegen Lochfraß und Spaltkorrosion in Chloridumgebungen.

Chemische Zusammensetzung: C≤0,03, Si≤1,00, Mn≤2,00, P≤0,045, S≤0,03, Cr:16,0-18,0, Mo:2,0-3,0, Ni:10,0-14,0

Verpackung

Es sind Rohrverpackungen, Einzelkartonverpackungen oder andere Industrieverpackungen erhältlich. Besondere Anforderungen sollten in der Bestellung erwähnt werden

Unser eigenes NSJ-Paket lautet wie folgt: